The starting system is the system that rotates the N2 spool until the engine becomes self sustaining.

System Components

- ATS (Air Turbine Starter)

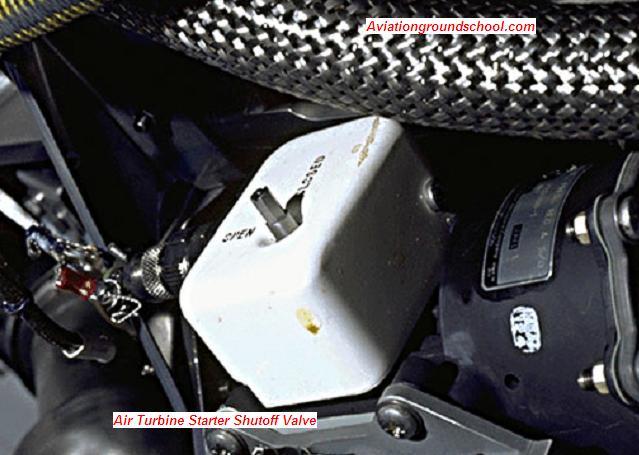

- ATS SOV (Air Turbine Starter Shutoff Valve

- Ground Starting Port

|

Use a right mouse-click in order to zoom in on the schematic!

|

|

This diagram shows #2 engine start cycle with the APU as a bleed source.

|

|

Starting Engine #2

Starting the aircraft is simple enough. The hardest part of the start is setting up the bleed panel. Set the panel up in the 1 O'clock and 3 lights configuration.

With the APU running and supplying the bleed air for the start make sure that the cross-bleed valve is in the "OPEN" position (1 O'clock). To initiate the start sequence, move

the Start switch to the "START" position. Keep your hand on the switch and then move it to back to "RUN". Don't move the switch to "START" then release it because it can go

past the "RUN" position and cancel the start cycle.

Once you initiate the start cycle, the rest of the start cycle is automatic. There are several things that you want to check for. The first thing you want to check for

is N2 rotation. This means that the Air Turbine Starter Shutoff Valve has opened. Then you should notice the oil pressure begin to rise almost immediately. If you don't this would

be a sign that the engine is not receiving any lubrication so shut the engine down before damage can occur.

At approximately 12% N2, you should see the ignition system energize by the annunciation of "IGN A" or "IGN B". Which exciter and igniter used is alternated by the FADEC automatically when the ignition selector is left in the

"AUTO" position.

Somewhere around 30% N2 you should see a Fuel Flow indication. Shortly there after you will see a rise in the ITT. Prior to lightoff, you will notice any risidual ITT decrease. This is due to the cooler air being moved

through the engine as the compressor sections spin.

Watch the ITT for indications of a "HOT START" or a "HUNG START". You can usually assume a "HOT START" when the ITT pointer moves past the 6 O'clock position on the EICAS. A "HUNG START" is when the engine does not continue to increase the

compressor speed. Usually it will hang up around 30 to 40% N2. This is a failure to lightoff because of lack of fuel flow or lack of ignition.

|

|

ATS SOV Message

Also you need to watch to make sure that you don't receive a message on the EICAS, "ATS SOV". This means that the air turbine starter shutoff valve has failed to close. The air turbine starter is still engaged. In this situation don't shut down the engine. Call the maintenance personel.

They will come out and manually close the ATS SOV. If there are no maintenance personel in the area, perhaps you are at an outstation. In any instance observe you starter limitations. In this instance the 5 minute dry motoring limitation will apply.

If you can't get the maintenance to close the valve prior to the limitation time expiring, shut the engine down. The only way to get the engine to shut down is to first remove the bleed air source from the start valve and then

turn the start switch to "STOP". Close the APU bleed valve or deselect the external air cart or close the cross-bleed valve if doing a cross-bleed start. If the maintenance dept. does close the valve manually, it is a good idea to shut the engine down and restart it. Check the ATS SOV indication does not come back on the second start. If it does, don't take the plane. If

you are flying and need to do a restart in the air you might have to shut the engine down even if you get it started again.

|

The ATS SOV access panel is located on the inboard side of the nacelle.

If everything is going fine up to this point, check for N1 rotation. This is an important part of the start cycle. You might run into a problem in the winter with a frozen N1 fan. The engine will continue to start however the

N1 fan will not turn. If the fan should happen to break free you will encounter severe vibrations that will shake the entire aircraft and could damage the engine. Shut the engine down early to avoid any damage.

Once the engine stabilizes, check for proper engine indications and make sure all the indications are in limits. Basically everything in the green band. A saying that is taught

is to check the indications from top to bottom. "2, 4, 6, 1/2, pressure, temperature, vibrations". What this equates to is as follows:

Indications

- 2 - N1 should be approximately 24%

- 4 - ITT should be in the 400 deg range

- 6 - N2 should be approximately 64%

- 1/2 -Fuel Flow should be approximately 350 or so. The half comes from half of the N2's 6 = 3

- Pressure - Should be in the green band.

- Temperature - Should be in the green band.

- Vibrations - Both N1 and N2 spool vibrations should be in the green band.

If all indications are normal, finish the start cycle by moving the FADEC knob to the "RESET" and then "ALT" positions. This will erase and reset any faults in the FADEC start cycle and will alternate to the other FADEC. It is important to observe the change in FADEC indications on the EICAS to make sure that if the

active FADEC fails, the stand-by will pick up. If you do not alternate FADECs after the start, you will not know if the other FADEC is good. Then if something happens to the active FADEC, you will lose the

engine because the stand-by FADEC is bad.

Starting Engine #1

After the pushback, make sure the towbar is disconnected and get cleared to start #1. You don't have to change the bleed configuration, just turn the Engine #1 start switch to "start" and continue like you did with engine #2.

|